Development Trends of Rigid-Flex PCB Technology

Ultra-Thin and High-Density

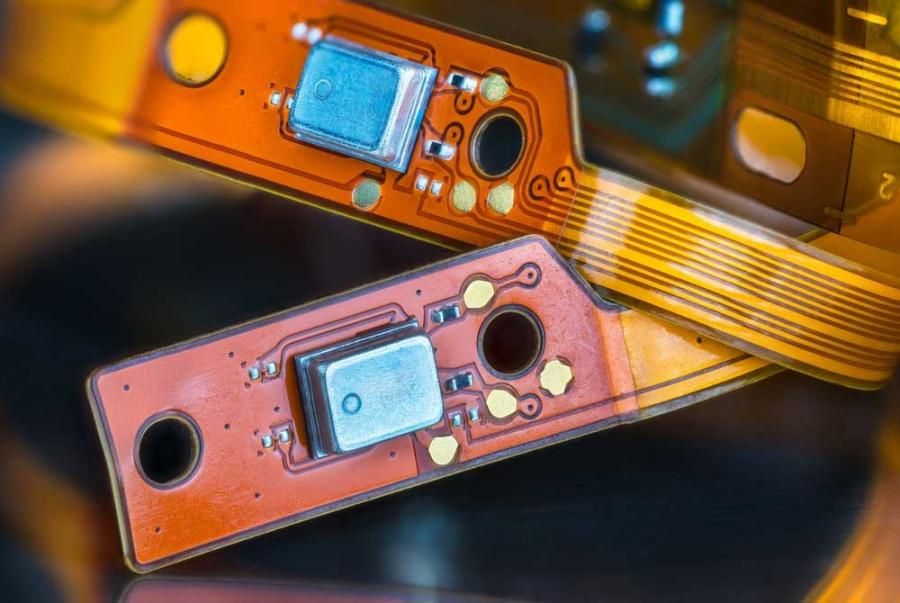

As electronic devices become increasingly miniaturized and feature-rich, there is growing demand for higher density and precision in PCB manufacturing. Rigid-flex PCBs will continue evolving towards ultra-thin and high-density designs to meet the market’s need for smaller, lighter, and more powerful electronic products.

New Materials and Processes

Advanced materials such as gallium nitride (GaN) and silicon carbide (SiC) are expected to be gradually adopted in the production of rigid-flex PCBs to enhance performance and reliability. Additionally, new processes like laser drilling and chemical copper plating will be introduced to improve manufacturing precision and efficiency.

Automation and Intelligence

With the rise of AI technology, the manufacturing process of rigid-flex PCBs will increasingly integrate intelligent elements, such as automated inspection and smart production. This will help boost production efficiency, reduce manufacturing costs, and improve the quality and reliability of the products.

Market Demand Trends for Rigid-Flex PCBs

Consumer Electronics

As innovation in consumer electronics like smartphones, tablets, and wearable devices continues to accelerate, the demand for rigid-flex PCBs will keep rising. These products often require circuit boards capable of bending and folding, and rigid-flex PCBs are well-suited to meet these requirements.

Automotive Electronics

The widespread adoption of electric vehicles and autonomous driving technology is fueling rapid growth in the automotive electronics industry. Due to their high reliability and flexibility, rigid-flex PCBs have promising applications in this sector.

Data Centers and Servers

With the increasing capital expenditure on global data centers, especially the accelerated deployment of AI servers, the demand for high-performance and high-density PCBs is growing. Rigid-flex PCBs, known for their excellent electrical and mechanical properties, hold significant potential in this field.

Competitive Landscape and Opportunities for Rigid-Flex PCBs

Competitive Landscape

The global PCB market is highly competitive, with both international giants and domestic players striving to increase market share. In the field of rigid-flex PCBs, companies like All Flex Solutions in the U.S. and Fine Circuit in South Korea hold significant market share and technological expertise.

China, as the world’s largest PCB manufacturing hub, has also seen the rise of competitive companies such as Zhongjing Electronics and Tower Union Technology, which are gaining ground in the rigid-flex PCB market.

Opportunities

Supportive government policies towards the electronics and information industries create a favorable environment for the development of rigid-flex PCBs.

Emerging technologies and diversified market demands also present new opportunities for growth. As technologies like 5G, the Internet of Things (IoT), and artificial intelligence (AI) continue to evolve rapidly, there is an increasing demand for high-performance PCBs. Rigid-flex PCBs are poised to capitalize on this wave, presenting vast growth opportunities for manufacturers.